Ove Lundager in the greenhouse with Philodendron Pink Princess Marble (left) and Philodendron Ring of Fire (right). Click here for the photo report of our visit to the nursery.

What started in 1985 as a nursery/garden center on the Jutland peninsula, in 2004, it moved to Odense, closer to the export companies, and began focusing entirely on the nursery activity. Today, the company has seven cultivation sites with 12 hectares of greenhouses. Although most of the production consists of plants in or for 6cm pots (up to 20 million units per year), there is also a greenhouse where plants are grown in 10.5, 12, and 15 cm pots (four million units/year). There are two sites for mini green plants, three where you will find only Peperomia, and a smaller production site for cacti and succulents.

Germany, the biggest market

Customers across Europe – retailers and garden centers – can find the complete range of mini green plants at the nursery. Only 13% of sales are done in Denmark itself. Germany is the largest destination, followed by France, Sweden, and Poland. Many products go to Dutch companies, although the Netherlands is often not the final destination. The company even has a daughter company there, Lundager BV, with two salespeople.

Ove says these little indoor plants are marketed year-round, though the first three months of the year and May are top months. “I think, after the Christmas plants, people want more greenery in their homes. Sales are lowest in summer and fall, but there’s only a 25% difference between January and July. We thus have work for all 160 of our employees all year. And in the summer, they can go on a nice vacation nicely without causing the company issues, because it’s less busy then. So, it works out well.”

According to Ove, you need a stable workforce, given the wide assortment. “Experience is vital. We have so many different products that it takes some time – up to six months – to learn all the items in a greenhouse and master the cultivation operations, though not everyone has to master all 500 varieties. After all, we have seven locations, each with its cultivation program.”

Competitive edge

Per week, 500,000 plants leave the nursery, making room for as many new plants. “We have 12 hectares under glass and 250 plants fit in one square meter. That’s quite a lot, so there’s significant stock investment. This scale is perhaps our main advantage over competitors. Most of the plants take three to six months to grow, though some stay in our greenhouse for up to a year, like cacti. We usually buy these, already a year old, from Italy. We also occasionally source ‘semi-finished’ products from Poland and final products from Thailand, but those are in negligible quantities,” Ove explains.

Although labor costs put Denmark at a competitive disadvantage compared to nurseries in southern Europe – planting and even packaging is still largely done by hand at nursery – Ove says the company has a few more advantages besides its size. “Last year we could produce more cheaply with residual heat from a power plant than companies that depend on gas. I’d also certainly count smooth logistics as an asset. Setting up a production facility in the Netherlands is, thus, an interesting idea.”

“We’d be very close to the exporters with whom we work, negating another logistical cost. But, we and many of our staff have years of experience here and know exactly how to work in the Danish climate. It’s not easy to just set up a new nursery and start doing that same thing in another country. And of course, with our extensive range, to which we occasionally add a new variety of our own, we have the edge over the competition in the market,” says Ove Lundager.

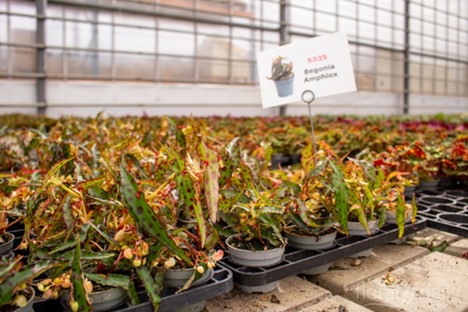

Begonia Amphioxus

Own varieties

Those new varieties come from either the company’s breeding program or external breeders. It is interesting for them to work with this Danish nursery, given its position in the market. “Breeding is long-term work, but having our own varieties is important because then you can come out with something unique. We sell licenses for our own protected varieties to growers around the world”

“Around five to ten percent of the trial plants eventually make it into the assortment,” adds Sales Director Rasmus Dupont Larsen. “That, however, mustn’t get much bigger. It’s already fairly complex regarding packaging, too, and clients shouldn’t be able to mess you around with countless varieties. Garden centers, of course, have other suppliers, and in the long run, it often becomes too much. Our best-selling plants are Calathea, Alocasia, Philodendron, and Peperomia. We are developing some new varieties that could soon make a difference.”

The LUNDAGER team in Denmark

‘TINGDAL by LUNDAGER’

The company’s emphasis has only recently shifted to Peperomias in bigger pots, more so when the company took over that part of Tingdal – another Danish nursery – that focuses on breeding and propagating this plant variety in September last year. “We even kept part of the brand name because it was very well-known in the industry. Now it’s called ‘TINGDAL by LUNDAGER’. That nicely reflects the past and the future,” says Rasmus.

Peperomias

Pots

Half the plants are shipped in pots to buyers, the other half not. “Or we deliver a trolley with plants and another with pots; that also happens. Then customers can choose the right pots for the plants themselves. Those pots are designed by Olga and Oliver Lundager and produced in China and Portugal. There are several qualities, depending on clients’ requirements and preferences. We supply both plastic and ceramic pots.”

Line of ceramics

Ever greener

These days, buyers do not only value quality, service, and aesthetics; they also increasingly consider the production process sustainability. “And rightly so,” continues Ove. “We, too, find that essential. We no longer use plant protection products and try to cultivate the plants as organically as possible. Our CO2 emissions have already dropped significantly with new screens and glass and by purchasing green energy from wind turbines. We want to do even more in the future. We could add more solar panels on the greenhouses’ roofs. That would immediately make us more energy independent. In this respect, I see we’re ahead of many others in the sector. We must, however, inform consumers more and better about this. Ultimately it’s also a marketing strategy.”

Mini green plants

According to Ove, the company’s mini green plants have a bright future. “Green plants are becoming increasingly popular, even among young people. And many consumers want something special. There are even people who’ll pay €1,000 for a specialty. So we definitely want to invest more in our already extensive business. We’re thinking of modernizing outdated, higher energy-cost greenhouses and expanding the greenhouse area by two to three hectares. We want to increase turnover by not only selling larger volumes but also by improving our client service in the form of, for instance, new varieties and a new line of ceramics,” Ove concludes.

Click here for the photo report of our visit to the nursery.

For more information:

Ove Lundager (CEO and owner)

LUNDAGER

33 Fangelvej, 5260, Odense, Denmark

Tel: +45 659 61 735

Email: ove@75012.dk

www.lundagerplants.com

Publication date:

Author: Elita Vellekoop

© FloralDaily.com